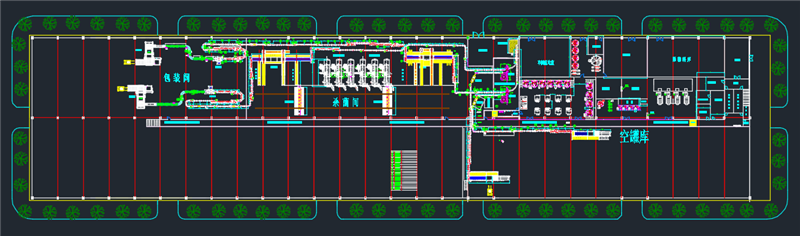

Automatic Depalletizer for Cans or Glass Bottles Stacks

Description

For packagers who need high level or ceiling height container discharge, this depalletizer is a reliable solution. It offers all the benefits of high level bulk depalletizing with the simplicity and convenience of a floor level machine, with an on-floor control station that makes it easy to manage operation and review line data. Designed with innovative features to maintain total bottle control from the pallet to the discharge table, and built for long-term production, this depalletizer is an industry-leading solution for bottle handling productivity.

Product Attributes

| Model NO. |

| KYCD800 |

| Warranty |

| 12 Months |

| Capacity |

| 800cans/ Min |

| Applicable Products |

| Cans, Glass Bottles |

| Power |

| 13kw |

| Weight |

| 11000kg |

| Power Supply |

| 3*380V*50Hz |

| Dimension |

| L15400mm*W3400mm*H4300mm |

Advantages

● Automatic encircling structure

● Automatic cardboard taking device

● Automatic empty pallet collection device

Parameters

| Production capacity | 800cans/ min |

| Applicable products | Cans, PE, PP |

| Total power | 13kw |

| Total weight | 11000kg |

| Power supply | 3*380V*50Hz |

| Control supply | DC24V/AC24V |

| Compressed air supply | 0.8Mpa |

| Gas consumption of air supply | 0.2m3/min |

| Adaptive size of whole stack (standard) | L1400mm*W1100mm*H2300mm |

| Can stack capacity | 3 stacks |

| Empty pallet stack capacity | 10 layers |

| Can conveying net chain | 6000mm |

| Dimension (standard) | L15400mm*W3400mm*H4300mm |

Application

Remove the containers such as cans, bottles from the stacks to the conveyor line

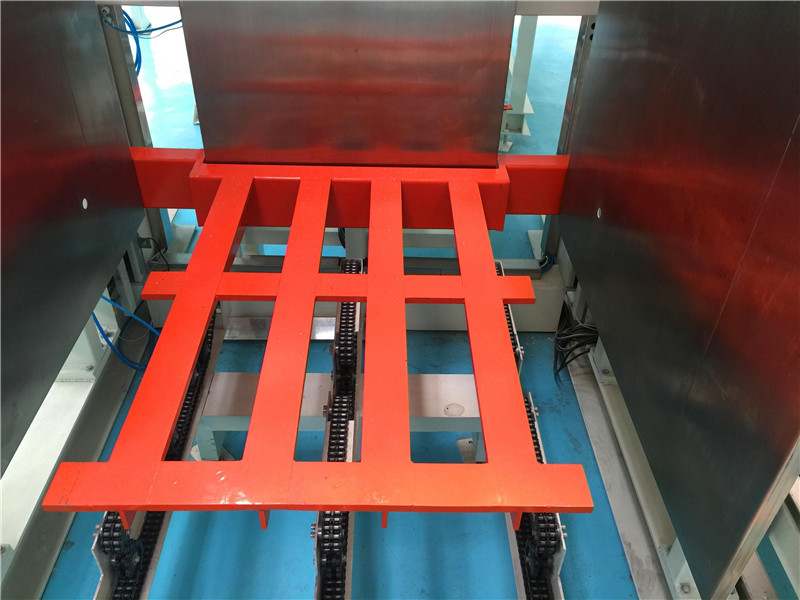

Whole stack transmission

1. High strength double row roller chain 12A with tensioning capacity(GB/T1243-1997)

2. With 3 stacks for preparation

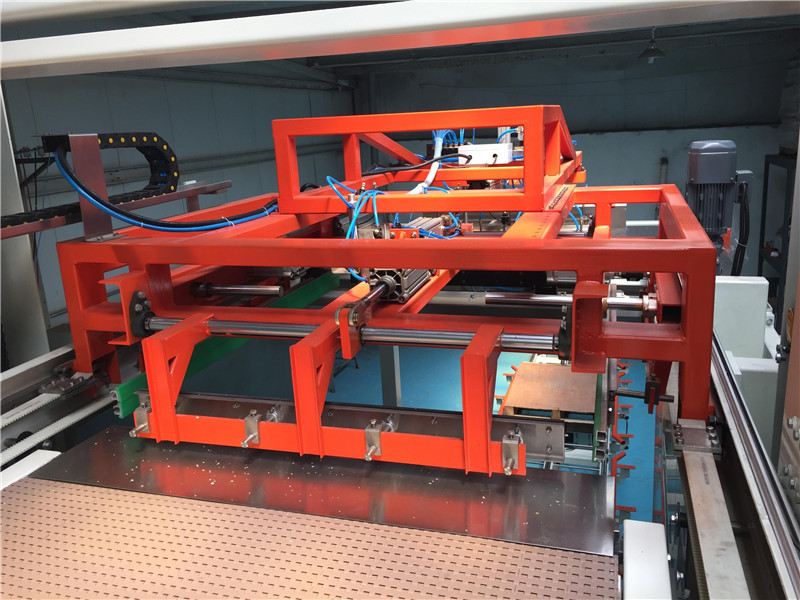

Stack guiding structure

1. Clamping plate

2. Pneumatic components: Taiwan (AirTac)、(SNS)

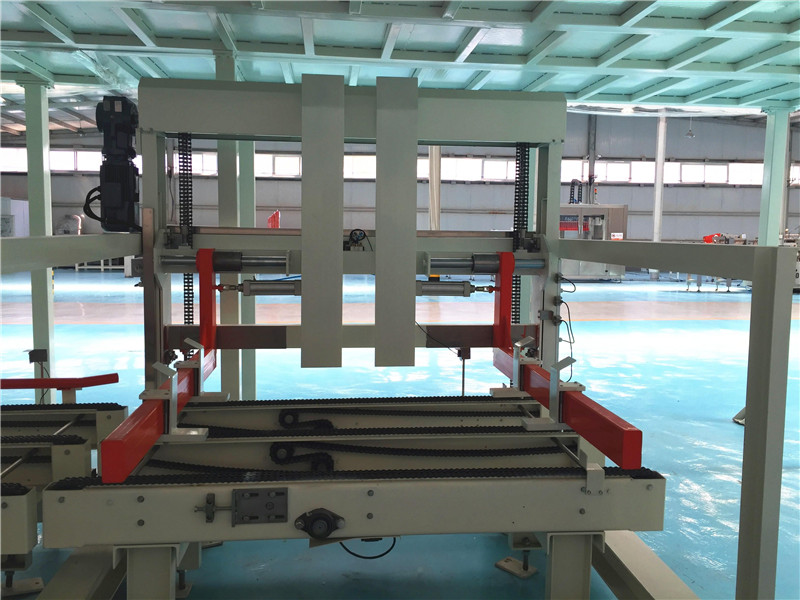

Stack Lifting

1. The lifting part is double-rail cantilever structure

2. High strength roller chain for power transmission (GB/T1243-1997)

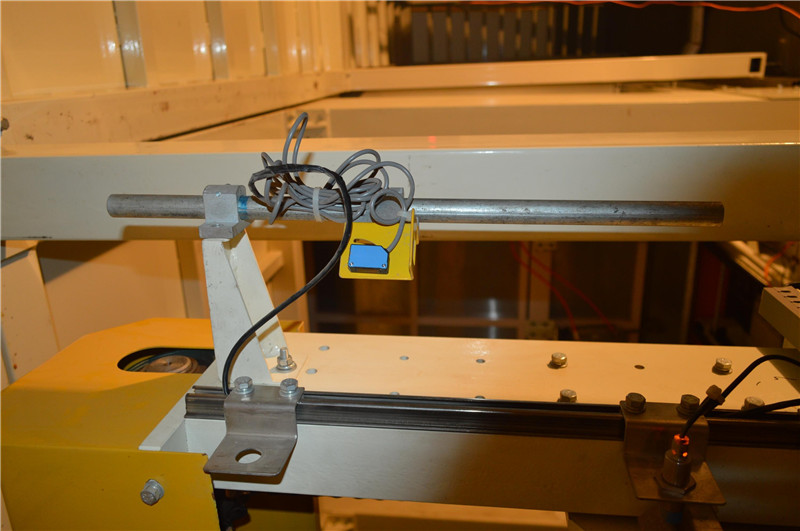

3. Photoelectric sensor for detection and position

Cans Unloading Structure

1. the action of unloading cans adopt encircling structure

2. power is self-braking electricity controlled by frequency conversion

3. pneumatic components:Taiwan (AirTac)、(SNS)

Conveyor

1. Side plate is made of 3mm carbon steel plate

2. Mesh belt is made of imported POM material

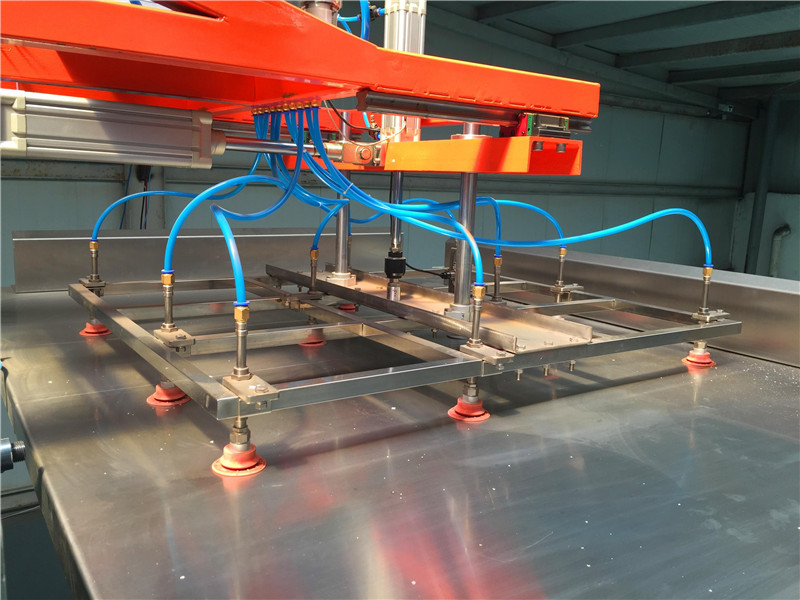

Automatic Sucking Structure

10 special custom organ sucker

Automatic Empty Palllet Collection

Frequency Conversion Control for Machine

Brand: denmark (Danfoss)

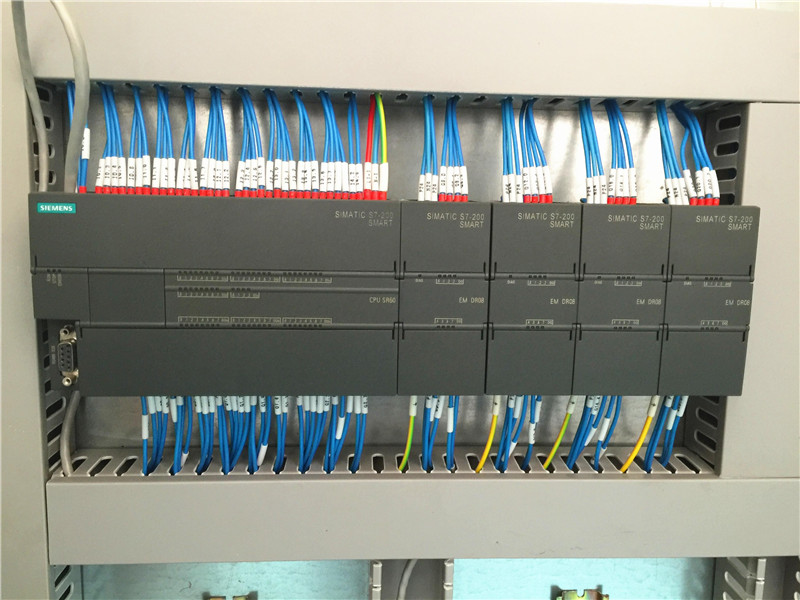

PLC control for machine

Brand: denmark (Siemens)

Touch Screen

Model: Taiwan (weinview)

Cans Production Line

Glass Bottle Production Line

Solution

Automatic depalletizer in walnut drink cans production line.