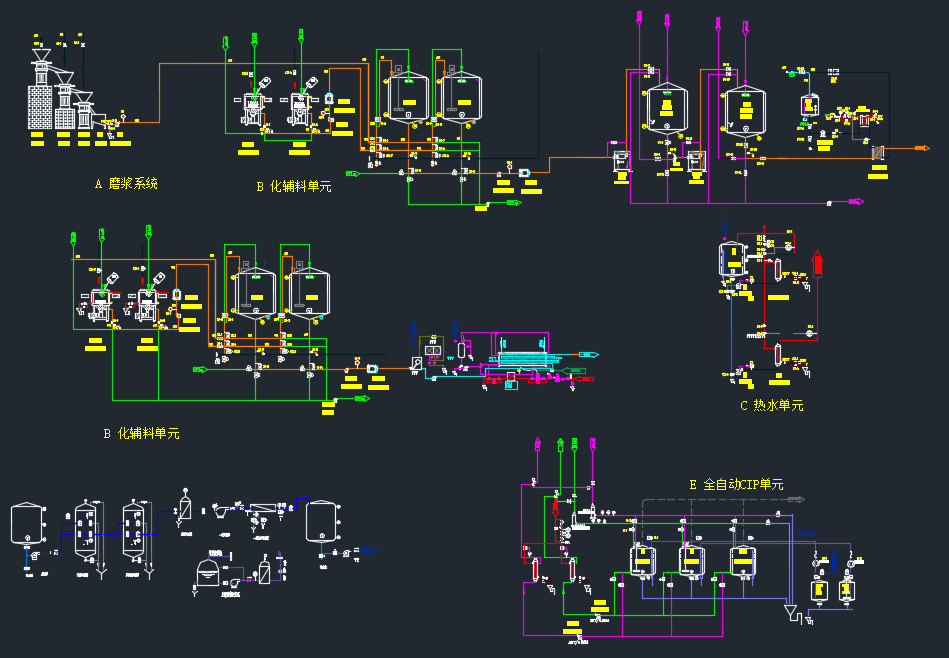

Beverage Blending System Complete Blending Beverage Processing Line

Description

The beverage blending system is made of high quality stainless steel and mirror-polished sanitary pipe materials, meeting food sanity requirement, whole system appears with exquisite and beautiful structure; This system adopts centralized distribution with divided zone,compact & concise layout,easy for maintenance; This system adopts full-auto integrated design,achieving one-touch operation, which is labor-saving, thus it improves productivity dramatically, at the same time,minimizes production and product safety accident.

Product Attributes

| Model NO. |

| KYQT10T |

| Warranty |

| 12 Months |

| Automatic Grade |

| Automatic |

| Capacity |

| 10000L/H |

Advantages

● 1. Different capacity according to customer need

● 2. Food grade standard ,314 or 316 stainless steel

● 3. Famous motor, pump and controlling system

Parameters

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory |

| Place of Origin | China |

| Brand Name | Sunrise |

| Material | SUS304/316L |

| Control type | PLC control |

Application

Dissolving of minor ingredients and sugar during production of energy drinks,fruit juice,herbal tea drinks,protein drinks etc;

Dissolving and reconstitution of powder ingredients in drinks production,such as fruit powder,tea powder,Collagen,inositol etc.

1. Blending System:

Food grade mixing tank with agitator adopts the high quality of SUS304L or SUS316L material and meet with the food grade. According to the customer's requirements, we can add jacket or insulation layer to meet the process needs. Mixing tank price is based on product capacity, and main accessories brands, etc.

2. Juice Pasteurizer:

Sunrise Intelligent Equipment Co., Ltd produces two types pasteurizers: plate type pasteurizes and tubular pasteurizers. It can be used in dairy/beverage/beer and other food industry. Sunrise pasteurizers have automatic control of sterilization temperature, automatic flow diversion and continuous recording for traceability together with high heat recovery for low operating cost. We adopt APV and other first-line brand high-efficiency plates.

3. CIP System:

CIP system is one of necessary cleaning equipment to clean the pipes and containers in dairy industry, beverage and pharmacy, and acts as a key role in ensuring product quality. Sunrise CIP system adopts a set of famous CPU as control center. We use famous touch screens to clearly describe the production process and operation steps which can control, display and visual fault alarm for the whole CIP station in real time. It consists of alkali tank, acid tank, hot water tank, clean water tank, recycle tank , heat exchangers, and pumps. Automatic adding of acid and alkali concentration is controlled by using conductivity meters which reduces the demand for manpower and ensures personal safety.

Beverage juice blending system

Solution

Beverage juice processing system

FAQ

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: How long the warranty will be?

A: We provide 12 months for the main parts of the machine and lifelong service for all the machineries.

Q: How to find sunrise machine?

A: Search Alibaba, Google, YouTube and find suppliers and manufacture and not traders. Visit exhibition in different countries. Send SUNRISE Machine an request and tell your basic inquiry. SUNRISE Machine sales manager will reply you in short time and add instant chatting tool.

Q: You are welcome to our factory at any time.

A: If we can fulfill your request and you interested in our products, you may pay a visit to SUNRISE factory site. The meaning of visiting supplier, because seeing is believing, SUNRISE with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

Q: How to guarantee your funds to be safe and delivery to be on time?

A: Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy. By letter of credit, you can lock the delivery time easily. After the factory visit, You can ensure the facticity of our bank account.

Q: See SUNRISE machine how to ensure the quality!

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years. Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years. After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

Q: The after-sale service of SUNRISE machine!

A: After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment. According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training. Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers' project.