Fruit and Vegetable Beverage Automatic Glass Bottle Hot Juice Filling Line

Description

Complete bottling lines and individual bottling equipment like fillers and bottle washing machines for glass bottles. Many of these lines are used for beverage but they are suitable for water applications as well. We provide wide variety of complete PET filling lines and cans filling lines in addition to these glass lines and related equipment.

Product Attributes

| Model NO. |

| KYGHF08A |

| Warranty |

| 12 Months |

| Packaging Material |

| Glass Bottle |

| Capacity |

| 8000bph |

| Total Power |

| 6kw |

| Outline Dimension |

| 5800mm×3000mm×2780mm |

| Weight |

| 9000kg |

| Height of The Bottle Feeding Distance Fr |

| 1050±50mm |

Advantages

⚡ 1. Up to 12000BPH

⚡ 2. Has CIP system

⚡ 3. Adopt micro negative pressure filling principle

⚡ 4. Can add one more set of washing part to warm glass bottles or sterilize the glass bottles

Parameters

| Item | Parameter |

| Applicable bottle type | glass bottle |

| Bottle diameter | φ50~106mm |

| Bottle height | 335±10mm |

| Filling type | High-level tank flow automatically, the negative pressure hot filling |

| Filling accuracy | ±5mm(liquid surface positioning) |

| Total water consumption | 0.3Mpa,2m³/h |

| Total air consumption | 0.8Mpa,0.1m³/min |

Application

Suitable for filling fruit juice, soy milk, walnut drinks, etc into glass bottles

Glass bottle filling machine is the SUNRISE company to adapt to the development of the market by independent research and development of the top products with the improvement of people's consumption level and the upgrading of consumption concept, in the beverage market, high nutritional value, beautiful packaging high-grade products have gradually become the market favorite, and glass bottle packaging just to meet the latter.

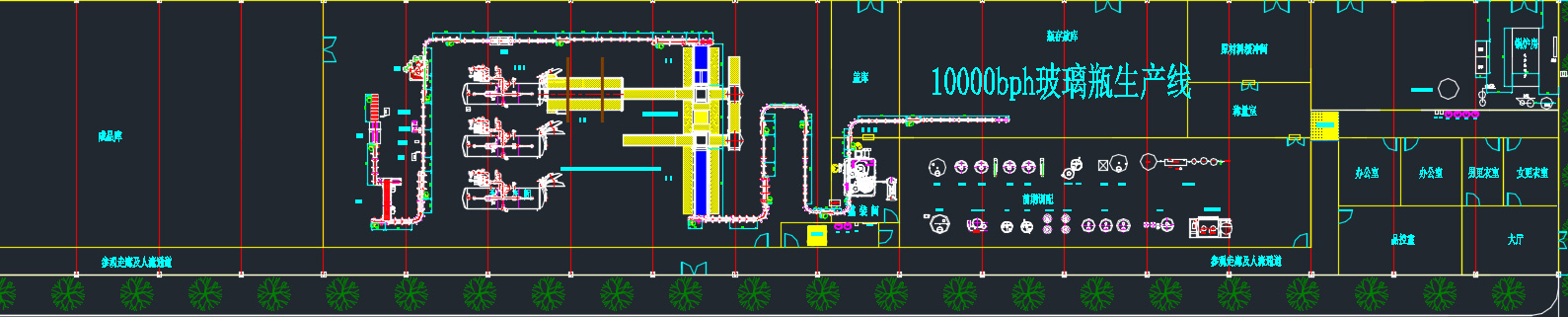

The glass bottle production line includes water treatment system, pre-treatment system, glass bottle three-in-one washing filling and capping machine, spray cooling and sterilization tunnel, labeling machine, carton packing machine and palletizing machine. SUNRISE can provide one-stop service, has a strong resource integration ability, to provide you with a comprehensive service.

Glass bottle filling machine in walnut drinks filling production line

Solution

Glass bottle filling machine in 10000BPH glass bottle walnut drinks filling production line

FAQ

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: How long the warranty will be?

A: We provide 12 months for the main parts of the machine and lifelong service for all the machineries.

Q: How to find sunrise machine?

A: Search Alibaba, Google, YouTube and find suppliers and manufacture and not traders. Visit exhibition in different countries. Send SUNRISE Machine an request and tell your basic inquiry. SUNRISE Machine sales manager will reply you in short time and add instant chatting tool.

Q: You are welcome to our factory at any time.

A: If we can fulfill your request and you interested in our products, you may pay a visit to SUNRISE factory site. The meaning of visiting supplier, because seeing is believing, SUNRISE with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

Q: How to guarantee your funds to be safe and delivery to be on time?

A: Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy. By letter of credit, you can lock the delivery time easily. After the factory visit, You can ensure the facticity of our bank account.

Q: See SUNRISE machine how to ensure the quality!

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years. Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years. After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

Q: The after-sale service of SUNRISE machine!

A: After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment. According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training. Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers' project.