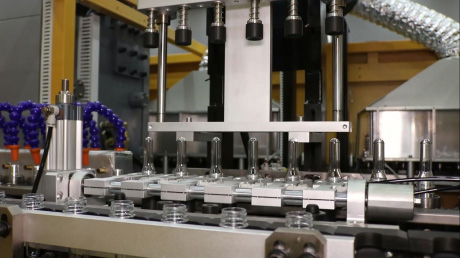

12000bph 500ml Automatic PET bottles Blow Moulding Machine

Description

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle, oil bottle, cosmetics, wide-mouth bottle and hot fill bottle etc.

Product Attributes

| Model NO. |

| KY-9E |

| Warranty |

| 12 Months |

| Automatic Grade |

| Automatic |

| Number Of Molds |

| 9 |

| Packaging Material |

| PET Bottle Preform |

| Capacity |

| 12000BPH |

Advantages

● 1. Full automatic running with theoretical output capacity up to 12000 bottles per hour for 0.7L volume using four-cavity blow mold.

● 2. Patented loading system carries the preform automatically with less moving parts.

● 3. Suitable to produce 0.1 ~ 0.7L Standard neck PET container.

● 4. Advanced PLC control system with a use-friendly control panel.

● 5. Built-in memory of the PLC saves all the sets of numbers required to produce different size bottles.

● 6. Multiple Reliable sensor systems monitors the machine's automatic function.

● 7. Equipped with special designed air storage unit.

● 8. Powerful heating unit with precision controller and convenient adjusting mechanism.

● 9. Cooling system that provides a perfect cooling result.

● 10. Compact design that saves space.

● 11. Simple installation & startup operation.

Parameters

|

Main machine |

Maximum Bottle capacity |

700ml |

|

Maximum output rate (bph) |

12,000 |

|

|

Maximum bottle diameter |

Φ68mm |

|

|

Neck diameter |

Φ18~38mm |

|

|

Maximum bottle height under neck |

<240mm |

|

|

Maximum preform height under neck |

<115mm |

|

|

Number of molds |

9 |

|

|

Heating part |

Number of heating modules |

6 |

|

Number of heating lamps |

8 |

|

|

Number of preform bases |

132 |

|

|

Air source |

Low pressure |

1Mpa |

|

Low pressure air consumption |

2m³/min |

|

|

High pressure |

3.5Mpa |

|

|

High pressure air consumption |

8m³/min |

|

|

Weight |

G.W. |

Around 9,000kg |

|

Dimension |

Main machine (L×W×H) |

5600×2600×2400mm |

|

Preform unscrambler(L×W×H) |

4500×3500×3500mm |

Application

Automatic blow molding machine is widely used to produce the carbonated bottle, mineral water, pesticide bottle, oil bottle, cosmetics, wide-mouth bottle and hot fill bottle etc.

Accurate preform-divided

• Servo driven equidistance preform-divided, safe, fast, and precise

Servo mold-Clamping

• Servo driven mold clamp, bottom mold and mold clamping linkage

• High-pressure mold-locked guarantee the bottle blowing speed and quality

Stable main transmission

• Servo driven stretch rods and main transmission

• Double limits

• Stretch rods can be auto adjusted, flexible and high precise

Safety mold framework structure

• Adopts drawer type structure, mold change and installation are safer and time-saving with special auxiliary tools

Intelligent operation system

• Human-machine interface control system, high automation, easy operation and safe

Standardized spare parts

• High-quality standardized spare parts guarantee the reliable and stability of the machines

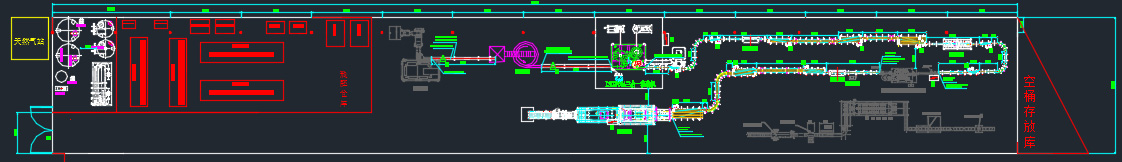

Automatic PET bottle blow moulding machine used in mineral water production line

Solution

12000BPH pure water bottling production line

FAQ

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: How long the warranty will be?

A: We provide 12 months for the main parts of the machine and lifelong service for all the machineries.

Q: How to find sunrise machine?

A: Search Alibaba, Google, YouTube and find suppliers and manufacture and not traders. Visit exhibition in different countries. Send SUNRISE Machine an request and tell your basic inquiry. SUNRISE Machine sales manager will reply you in short time and add instant chatting tool.

Q: You are welcome to our factory at any time.

A: If we can fulfill your request and you interested in our products, you may pay a visit to SUNRISE factory site. The meaning of visiting supplier, because seeing is believing, SUNRISE with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

Q: How to guarantee your funds to be safe and delivery to be on time?

A: Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy. By letter of credit, you can lock the delivery time easily. After the factory visit, You can ensure the facticity of our bank account.

Q: See SUNRISE machine how to ensure the quality!

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years. Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years. After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

Q: The after-sale service of SUNRISE machine!

A: After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment. According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training. Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers' project.