KUSP Type Stainless Steel Conveyor Chain Good Rigidity

Description

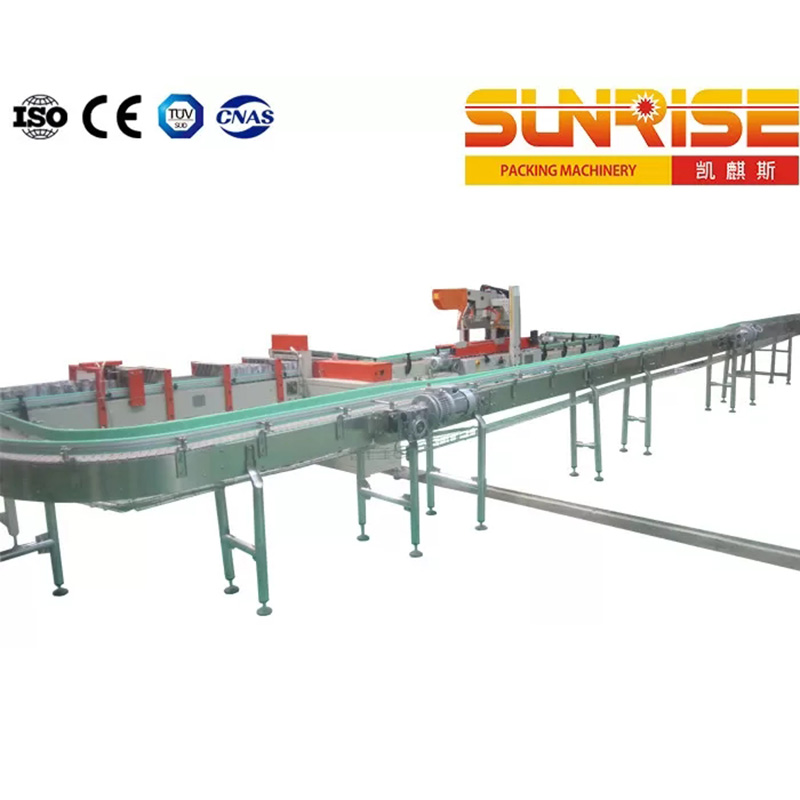

The layout of our company's production line fully considers the needs of customers' investment and production line efficiency, and improves on the basis of introducing foreign technology to meet the delivery requirements of various production lines. The system adopts foreign advanced technology and a new design of improved mechanical structure. Most of the components are formed by stamping or bending, which has the advantages of good rigidity, light weight and good interchangeability. Reliable operation, convenient maintenance, suitable for conveying cans (bottles) with a diameter of φ40~φ110 mm. Pressure-less conveying system, relying on real-time speed signal acquisition and feedback and automatic differential speed control system, can realize that the cans (bottles) on the conveyor belt can be smoothly changed from multiple rows to single rows in the moving state without mutual extrusion. The electrical control system adopts PLC to control the operation of the entire solid tank (bottle) conveying buffer system, and automatically realizes the functions of speed acceleration and deceleration and automatic buffering.

Product Attributes

|

Material: |

SUS304 |

|

Landing Leg: |

50*50mm |

|

Conveyor Chain |

8.7mm thickness |

|

Conveyor Wheel |

High strength material |

|

Water Pan |

SUS304 |

|

Control Cabinet |

SUS304 |

Advantages

Good Rigidity, Light Weight, Good Interchangeability

Application

Remove the containers such as cans, bottles from the stacks to the conveyor line

Main Structure And Characteristics

1. The side plate is 2.5mm thick high-quality SUS304, laser cutting and bending.

2. The outriggers are 50X50 stainless steel square tubes.

3. Outrigger brackets and guardrail brackets are all SUS304 stamping parts with beautiful appearance.

4. The concentrator and fixing frame are made of SUS304 material.

5. The guardrail is made of stainless steel M strips, and the pad rails are aluminum alloy frames and high molecular polyethylene wear-resistant strips.

6. The connecting rod is made of SUS304 stainless steel, and the drive shaft is 40mm diameter 45 steel.

7. The chain plate can adopt two specifications of 8.7mm thick high-speed chain plate and 4mm chain plate. The 8.7mm thick 25.4-pitch high-speed chain plate has low noise, stable operation, low bottle pouring ratio, high strength, long life, and high sprocket. Strength material (choose according to customer requirements).

8. The multi-row and single-row chain lanes adopt differential lane change to reduce tank extrusion and wear.